Ducati Scrambler 800 - Service manual > Shimming the shafts

Ducati Scrambler 800 - Service manual > Shimming the shafts

Before assembling the crankcase halves, it is necessary to calculate the shim that determines the end float of the crankshaft and of the gearbox shafts. Calculate the shimming following the procedures described below.

Shimming the crankshaft

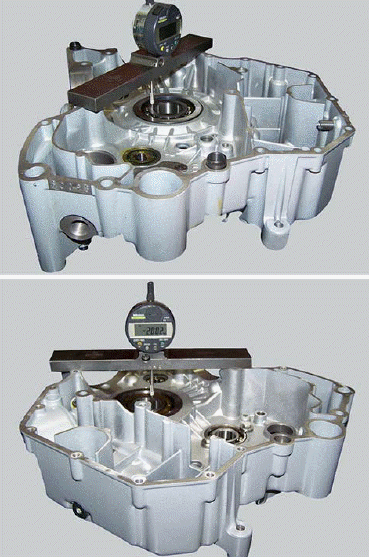

After having installed the new main bearings proceed as follows to determine the total "SA" height of the shimming:

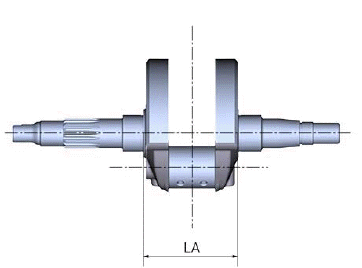

Measure value "LA" between the bearing supporting surfaces on the crankshaft;

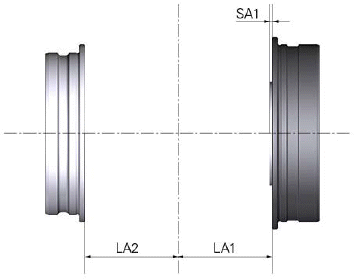

Measure "LA1" and "LA2" corresponding to the distance from the mating surface between the crankcase halves to the mating surface of the bearing inner ring;

Add a pre-load of 0.30 mm to allow the axial-type bearings of the crankshaft to correctly settle in their seat.

The result will be: SA=LA-LA1-LA2-0.30.

The obtained result is the shimming value.

Reassembling the crankcase halves

The crankcase halves must be in good condition and perfectly clean. The mating surfaces must be perfectly flat and free from burrs.

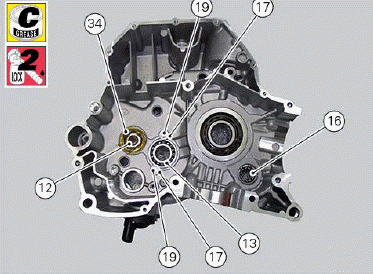

Refitting the clutch-side crankcase half

The following parts must be present on the internal side of the crankcase half:

- the secondary shaft end bearing (12); apply grease on the bearing rollers. Drive the inner race (34), removed previously, fully home in the bearing. Apply grease to the inner race;

- the primary shaft bearing (13), secured with the screws (19) and the retaining spacer (17); apply recommended threadlocker to the screws (19), and tighten to a torque of 10 Nm (Min. 9 Nm - Max. 11 Nm);

- the roller bearing (16) with circlip (35) installed at the timing layshaft.

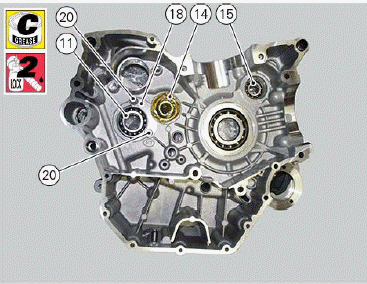

Refitting the generator-side crankcase half

The following parts must be present on the internal side of the crankcase half:

- the double-race ball bearing (11) supporting the selector fork shaft.

Apply threadlocker to the screws (20). Fit retainer plate (36) on gearbox secondary shaft bearing (11) starting the screws (20) on chain-side crankcase half.

Note The bearing retainer plate must be positioned with the holes tapering facing upwards.

Tighten the screws (20) to a torque of 10 Nm (Min. 9 Nm - Max. 11 Nm). The gearbox primary shaft end bearing (14) with inner spacer (21): apply grease on the bearing needle rollers.

Drive the inner race (37), removed previously, fully home in the bearing.

Apply grease to the inner race.

The main bearing (9).

The ball bearing (15) with circlip (36) at the timing layshaft, aiming it so that the plastic cage closed side is facing the crankcase half.

Note Bearings do not have a specific mounting position (except main bearings), however it is good practice to install the bearings so that the written side is facing inwards.

See also:

Ducati Scrambler 800 - Service manual > Closing the crankcase

Ducati Scrambler 800 - Service manual > Closing the crankcase

If previously removed, apply specified threadlocker to dowel (28) and tighten to a torque of 15 Nm (Min. 13 Nm - Max. 17 Nm). After tightening, remove the excess of threadlocker.

Ducati Scrambler 800 - Service manual > Main bearings

Ducati Scrambler 800 - Service manual > Main bearings

To replace the bearings proceed as follows: heat the crankcase half in an oven to 100 ВєC; remove the bearing using a drift and hammer; install the new bearing (while the crankcase is still hot) keeping it perfectly square in its seat using a tubular drift that only bears on the outer ring of the bearing; allow the parts to cool and check that the bearing is securely fastened to the crankcase half.

Ducati Scrambler

Ducati Scrambler Fantic Caballero 500

Fantic Caballero 500 Indian FTR 1200

Indian FTR 1200 Moto Guzzi V85 TT

Moto Guzzi V85 TT Royal Enfield Bullet Trials Works Replica

Royal Enfield Bullet Trials Works Replica Triumph Scrambler 1200 XE

Triumph Scrambler 1200 XE Triumph Street Scrambler

Triumph Street Scrambler Yamaha XSR700

Yamaha XSR700 Ducati Scrambler 800

Ducati Scrambler 800 Moto Guzzi V85 TT

Moto Guzzi V85 TT Triumph Scrambler 1200 XC

Triumph Scrambler 1200 XC