Ducati Scrambler 800 - Service manual > Main bearings

Ducati Scrambler 800 - Service manual > Main bearings

To replace the bearings proceed as follows:

- heat the crankcase half in an oven to 100 ВєC;

- remove the bearing using a drift and hammer;

- install the new bearing (while the crankcase is still hot) keeping it perfectly square in its seat using a tubular drift that only bears on the outer ring of the bearing;

- allow the parts to cool and check that the bearing is securely fastened to the crankcase half.

Check that the gap between crankcase and fitted bearings is not lower than 0.03 mm, otherwise replace the crankcase halves.

Overhauling the crankcase halves

Visually inspect the engine crankcase halves.

Check that the surfaces of the crankcase halves are perfectly flat using a reference surface.

Check bearing (9) and (10) conditions.

If they need to be replaced, it is necessary to replace them in pairs.

Warning When overhauling an engine it is good practice to replace all the crankcase bearings.

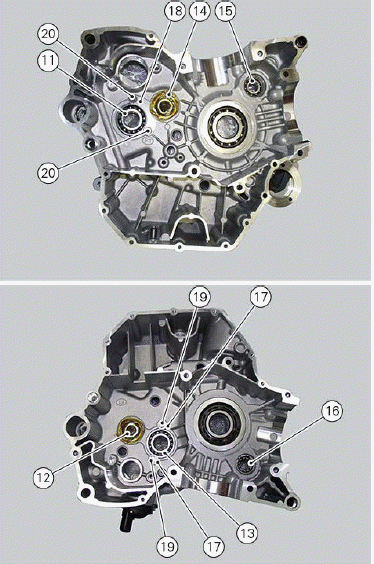

Replace the bearings (11) and (12) on the ends of the gearbox secondary shaft and timing layshaft bearings (15) and (16).

When replacing bearings (13) and (14) supporting the gearbox primary shaft, block them on the crankcase half with spacers (17) and stop plate (18) respectively fixed by screws (19) and (20).

Upon each overhaul it is recommended to replace also the seal ring located between bearing (14) and chain-side crankcase half: lubricate the ring with denatured alcohol, introduce it fully home in the crankcase half as shown in the figure.

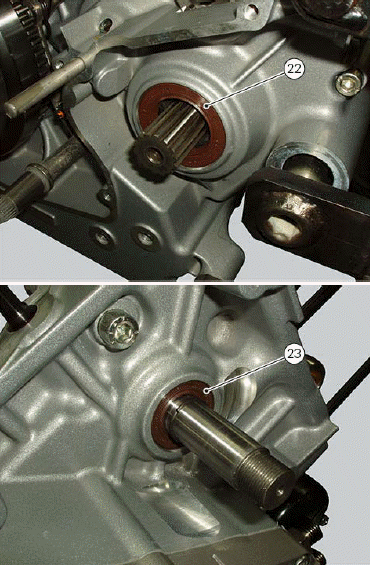

At each overhaul it is recommended to replace also the sealing ring (22) and the seal ring (23).

In case of needle roller bearing replacement on the swingarm shaft, proceed as follows:

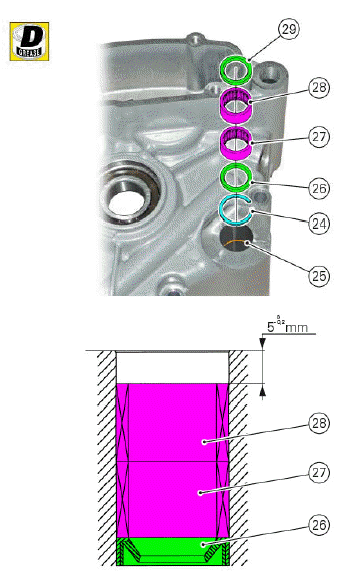

Chain-side crankcase half

Fit snap ring (24) in hole (25).

Smear specified grease inside hole.

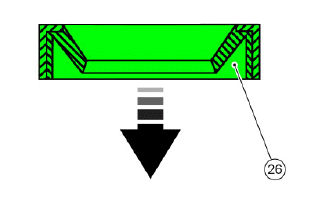

Fit seal ring (26) and the two bearings (27) and (28) respecting the indicated value.

Orient the seal ring (26) as shown. The arrow refers to the insertion direction.

Clutch-side crankcase half

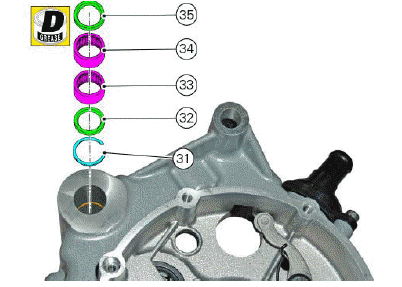

Fit snap ring (31) in the hole.

Smear specified grease inside hole.

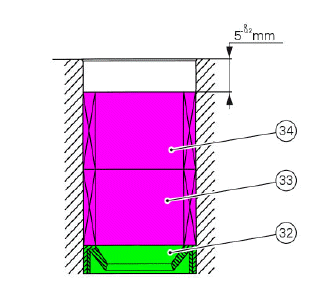

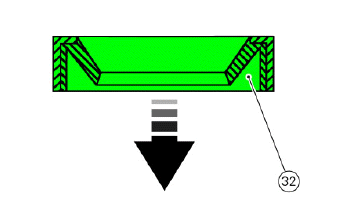

Fit seal ring (32) and the two bearings (33) and (34) respecting the indicated value.

Orient the seal ring (32) as shown. The arrow refers to the insertion direction.

Separating the crankcase halves

Remove the engine from the frame (Removing the engine).

Remove the clutch cover (Removing the clutch cover).

Remove the complete clutch unit (Removing the clutch).

Remove the oil pump (Removing the oil pump).

Remove the generator cover (Removing the generator cover).

Remove the heads (Removing the engine heads).

Remove the cylinder (Removing the cylinder/piston assembly).

Remove the starter motor idler gear (Removing the starter motor idler gear).

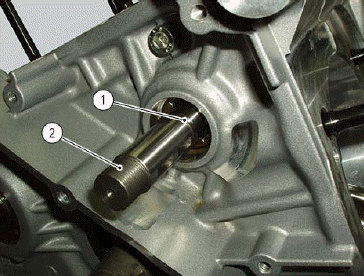

Use two screwdrivers to remove the snap ring (1) from the timing layshaft (2) on the clutch-side crankcase half.

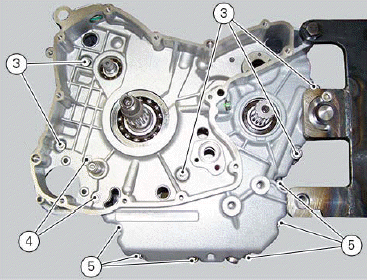

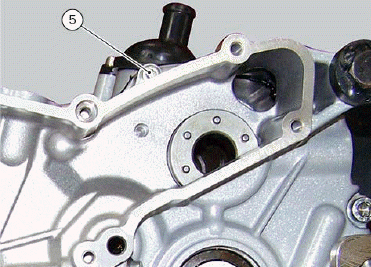

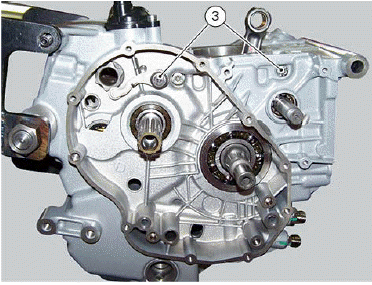

Loosen crankcase half jointing screws (3), (4) and (5) on generator side.

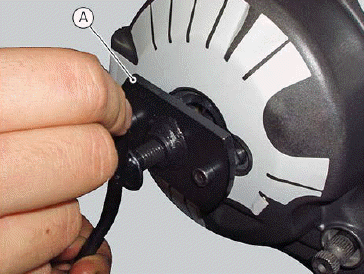

Reuse the generator cover or a service cover with puller (A) part no. 88713.1749 fitted. Secure cover to crankcase half with some of the original screws and begin separation by turning the central pin of the tool.

Tap the end of the gearbox secondary shaft with a plastic mallet to separate the crankcase halves.

Remove the gearbox shafts and the gearbox selector drum from the crankcase halves.

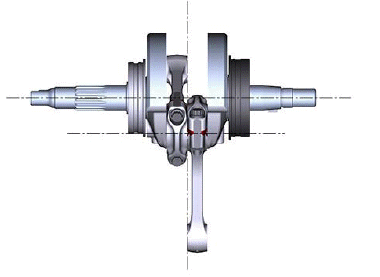

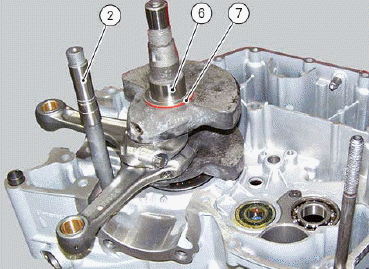

Drive out the crankshaft (6) using a plastic mallet, paying attention not to damage washers (7).

Remove the timing layshaft (2).

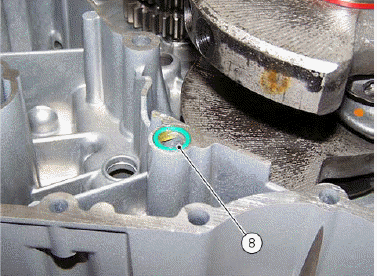

Recover O-ring (8) in the oil passage between crankcase halves.

See also:

Ducati Scrambler 800 - Service manual > Shimming the shafts

Ducati Scrambler 800 - Service manual > Shimming the shafts

Before assembling the crankcase halves, it is necessary to calculate the shim that determines the end float of the crankshaft and of the gearbox shafts. Calculate the shimming following the procedures described below.

Ducati Scrambler

Ducati Scrambler Fantic Caballero 500

Fantic Caballero 500 Indian FTR 1200

Indian FTR 1200 Moto Guzzi V85 TT

Moto Guzzi V85 TT Royal Enfield Bullet Trials Works Replica

Royal Enfield Bullet Trials Works Replica Triumph Scrambler 1200 XE

Triumph Scrambler 1200 XE Triumph Street Scrambler

Triumph Street Scrambler Yamaha XSR700

Yamaha XSR700 Ducati Scrambler 800

Ducati Scrambler 800 Moto Guzzi V85 TT

Moto Guzzi V85 TT Triumph Scrambler 1200 XC

Triumph Scrambler 1200 XC