Ducati Scrambler 800 - Service manual > Disassembling the rear brake control

Ducati Scrambler 800 - Service manual > Disassembling the rear brake control

The brake master cylinder is supplied only as a complete unit; internal components cannot be replaced.

To disassemble the master cylinder's outer parts, follow the indications given in the exploded view at the beginning of this Section.

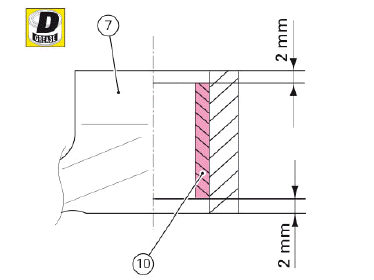

If the bush (10) inside the brake pedal (6) needs to be replaced, grease the external surface and fit the new bush using a press to insert it. The bush must be placed at 2 mm from the pedal external face.

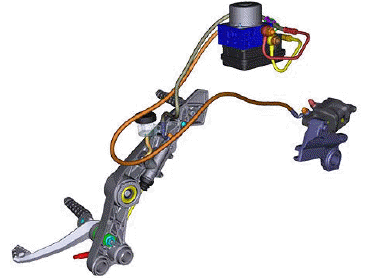

To disassemble the various parts of the system, refer to the exploded view at the beginning of this chapter.

After performing an operation on the rear brake control, check the brake pedal position following the instructions detailed in Section "Adjusting the position of the gear pedal and rear brake pedal".

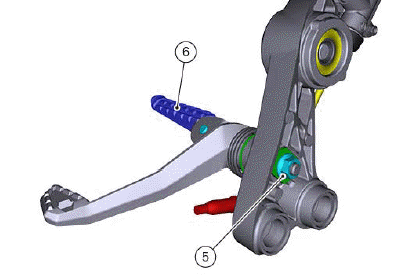

Removing the rear brake control

Warning The brake master cylinder manufacturer advises against servicing the brake master cylinder due to the safety critical nature of this component. Incorrect overhaul can endanger rider and passenger safety.

Maintenance operations on these units are limited to replacement of the following parts: control lever, fluid reservoir assembly and relative fasteners and master cylinder fasteners.

Drain the rear braking system (Changing the rear brake system fluid).

Remove the footpeg holder plate.

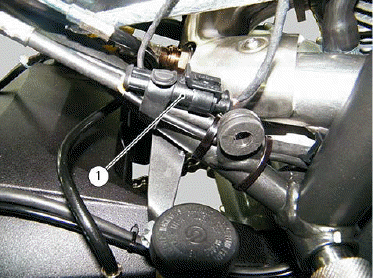

Disconnect rear stop switch (1) from main wiring.

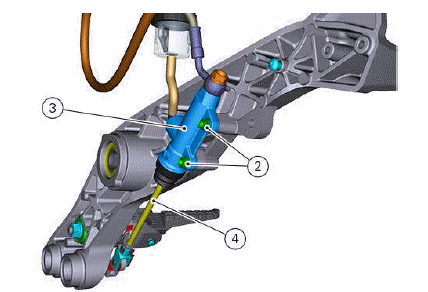

Loosen rear brake master cylinder retaining screws (2). Slide out rear brake master cylinder (3) from adjuster rod (4).

Loosen nut (5) securing the RH footpeg (6).

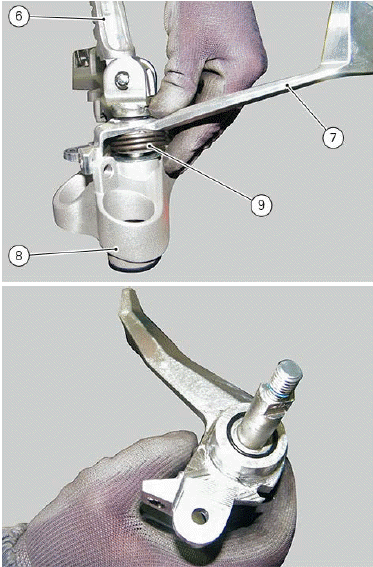

Slide out brake control lever (7) and footpeg (6) of the footpeg holder plate (8).

Collect washer (9).

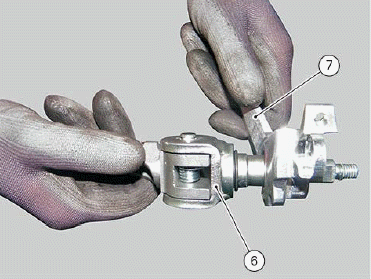

Separate bracket (6) and lever (7).

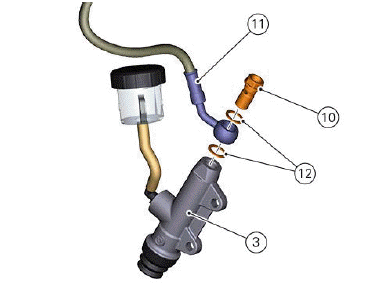

Undo special screw (12) from master cylinder (3) and slide out hose (11), collecting seals (12).

Remove rear brake master cylinder (3) from vehicle.

See also:

Ducati Scrambler 800 - Service manual > Refitting the rear brake disc

Ducati Scrambler 800 - Service manual > Refitting the rear brake disc

Position brake disc (2) on wheel (3) and the phonic wheel (4) on the disc. Tighten the screws (1) with pre-applied threadlocker to a torque of 25 Nm +- 5%, in a cross pattern.

Ducati Scrambler

Ducati Scrambler Fantic Caballero 500

Fantic Caballero 500 Indian FTR 1200

Indian FTR 1200 Moto Guzzi V85 TT

Moto Guzzi V85 TT Royal Enfield Bullet Trials Works Replica

Royal Enfield Bullet Trials Works Replica Triumph Scrambler 1200 XE

Triumph Scrambler 1200 XE Triumph Street Scrambler

Triumph Street Scrambler Yamaha XSR700

Yamaha XSR700 Ducati Scrambler 800

Ducati Scrambler 800 Moto Guzzi V85 TT

Moto Guzzi V85 TT Triumph Scrambler 1200 XC

Triumph Scrambler 1200 XC