Ducati Scrambler 800 - Service manual > Refitting the cylinder heads

Ducati Scrambler 800 - Service manual > Refitting the cylinder heads

Warning To prevent oil leaks in the contact area between cylinders and crankcase, each time the head is removed, cylinder and piston must be removed as well to clean the mating surfaces of crankcase and cylinder and restore the worn gaskets and O-rings and apply again sealing compound.

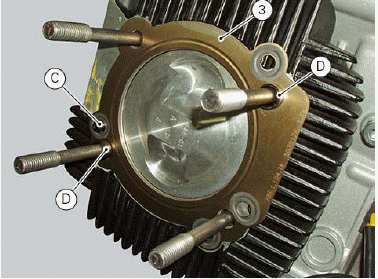

Before fitting the complete heads replace the head gasket (3) and check that there are the reference pins (C) and bushings (D).

Fit the complete head on the casing stud bolts and bring it fully home on the cylinder.

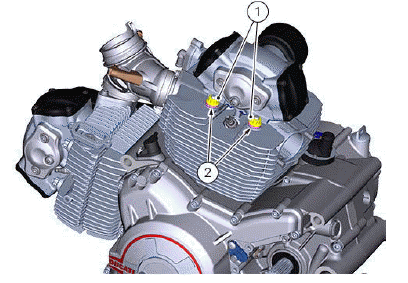

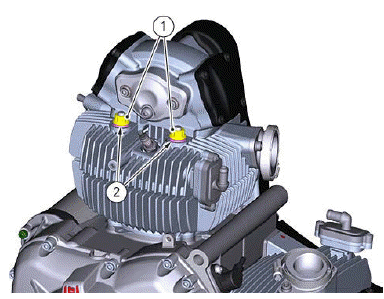

Fit the special washers (2) in the stud bolts with the sharp edge facing the head and the flat side facing inside.

Grease the nut (1) underhead and the stud bolt thread with specified grease.

Use tool no. 88713.2676 with a torque wrench to tighten the retaining nuts, following a cross pattern, first to a snug torque of 15 Nm (Min. 13 Nm - Max. 17 Nm), then to a pre-load torque of 30 Nm (Min. 28 Nm - Max. 32 Nm), then to a final tightening torque of 48 Nm (Min. 46 Nm - Max. 50 Nm)

Important Failure to follow the described procedure may cause an abnormal stretch of the stud bolts and serious damages to the engine.

Refit the engine in the frame.

Refitting the valves and rocker arms

To refit them follow the removal reverse procedure, paying attention to the operations that are specifically indicated.

It is extremely important to thoroughly clean all components.

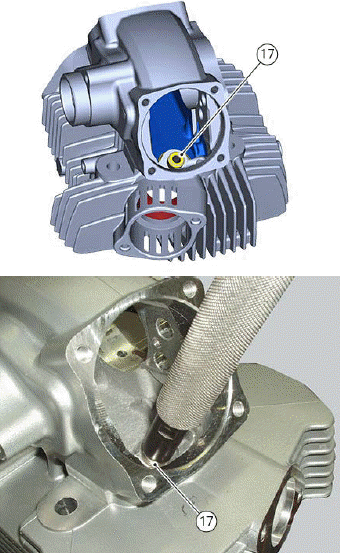

If seal rings (17) of the valve guides have been removed, fit new ones after lubricating them with engine oil and fit them on the side with spring on tool no. 88713.2442.

Fit the end of the tool into the valve guide and use a hammer to tap the sealing rings (17) home into the valve guides.

Refitting rocker arms, shims and valves

Closing rocker arm

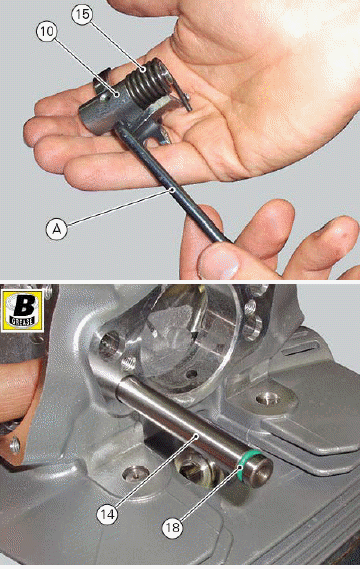

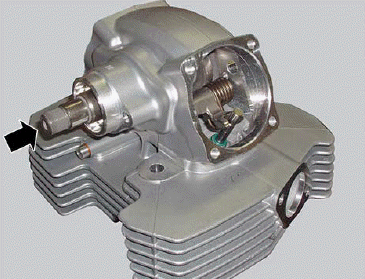

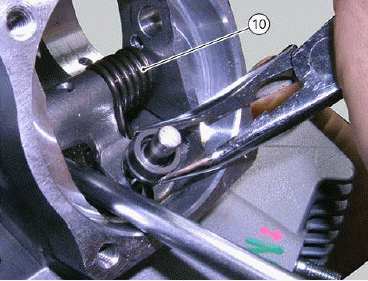

Fit on tool (A) no. 88713.2783 the closing rocker arm (10) and the relevant spring (15).

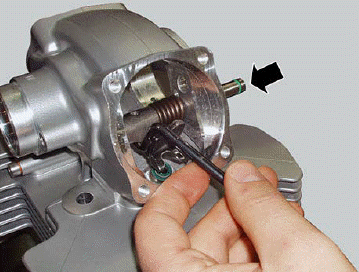

Fit the tool-rocker arm-head spring assembly and shaft (14) with a new lubricated seal.

Important When refitting the rocker arm shafts, make sure that the threaded hole is on the head outer side.

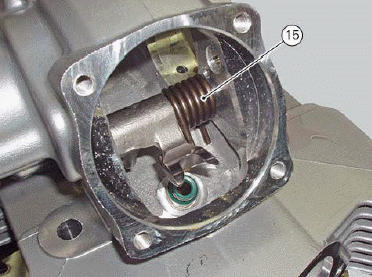

Release spring (15) and remove tool (A) no. 88713.2783.

Follow the same procedure on the exhaust side.

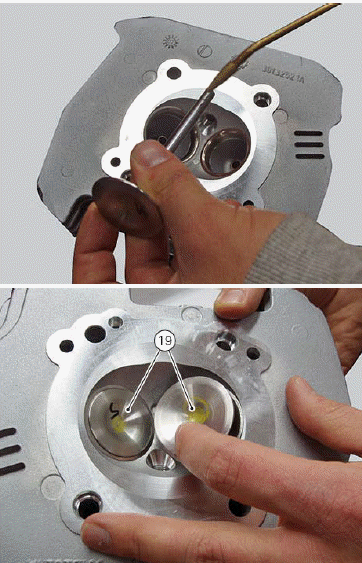

Lubricate valves (19) with engine oil and fit them.

Temporarily fit the camshaft.

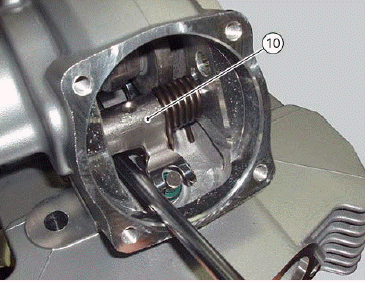

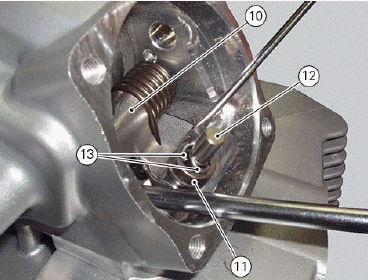

Use a suitable tool to block the closing rocker arm (10) in the position with valve open.

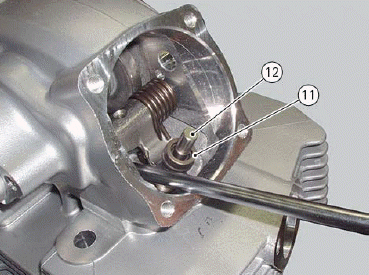

Fit the closing shim (11) with the bigger diameter side facing down in the valve stem (12).

Position the two split rings (13) on the valve stem.

Remove the screwdriver and position the closing rocker arm (10) in its rest position.

Use a suitable tool to compress the spring as much as possible while holding valve, shim and split rings in the valve closed position.

Release the closing rocker arm (10) with a quick movement, so that the split rings seat in the shim.

With the valve in rest position and by counter-holding the return spring, push on the rocker arm and check that the clearance between the rocker arm sliding shoe and the closing shim is the specified one.

If this is not the case, adjust the valve clearance.

Once the specified clearance is reached, remove the temporarily-fitted camshaft, lubricate it with oil and reposition it on the cylinder head.

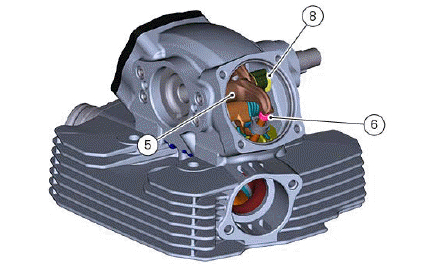

Opening rocker arm

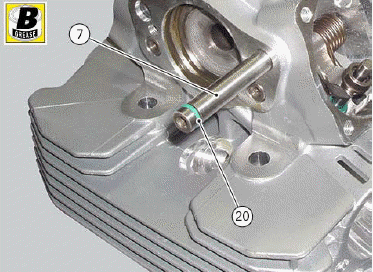

Insert rocker arm shaft (7) with the threaded hole on the head external hole: seal (20) must be replaced upon every reassembly operation and the new one must be duly lubricated.

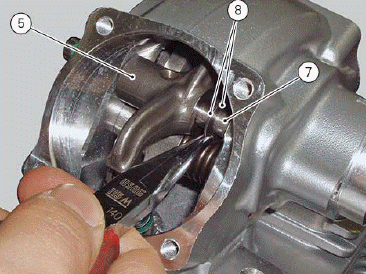

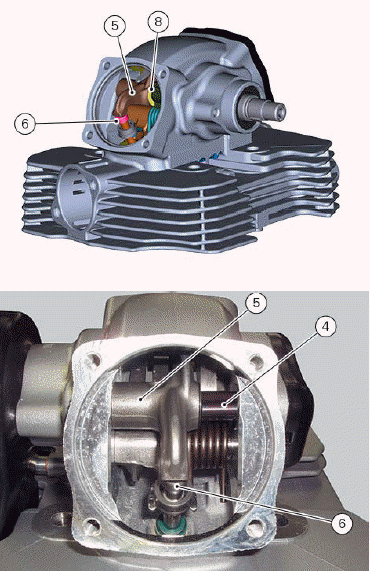

Position the opening rocker arm (5) and two shims (8) on shaft (7).

Refit the timing side cap (Refitting the camshafts).

Refit the timing pulleys (Refitting the cylinder head pulleys).

Position the valve opening shim.

With the valve in rest position, check that the clearance between rocker arm and the relevant adjuster is the specified one.

If this is not the case, adjust the valve clearance.

Fit the lateral spring (4) on shaft (7) of the opening rocker arm (5) between the two spacers (8).

Refit the caps, the camshafts and the valve covers (Refitting the camshafts).

See also:

Ducati Scrambler 800 - Service manual > Overhauling the cylinder head components

Ducati Scrambler 800 - Service manual > Overhauling the cylinder head components

Overhauling the heads Remove any carbon deposits from the combustion chamber and its ducts. Check for cracking and inspect the sealing surfaces for scoring, steps or other damage.

Ducati Scrambler

Ducati Scrambler Fantic Caballero 500

Fantic Caballero 500 Indian FTR 1200

Indian FTR 1200 Moto Guzzi V85 TT

Moto Guzzi V85 TT Royal Enfield Bullet Trials Works Replica

Royal Enfield Bullet Trials Works Replica Triumph Scrambler 1200 XE

Triumph Scrambler 1200 XE Triumph Street Scrambler

Triumph Street Scrambler Yamaha XSR700

Yamaha XSR700 Ducati Scrambler 800

Ducati Scrambler 800 Moto Guzzi V85 TT

Moto Guzzi V85 TT Triumph Scrambler 1200 XC

Triumph Scrambler 1200 XC