Ducati Scrambler 800 - Service manual > Ignition spark plug

Ducati Scrambler 800 - Service manual > Ignition spark plug

To check the spark plug, refer to chapter "Replacing the spark plugs".

Temperature sensor

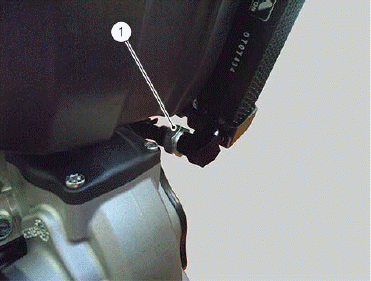

The air temperature sensor (1), located on vehicle central part, detects the ambient temperature.

The detected signal is sent to the control unit, that shares it through the CAN line with the instrument panel; this allows performing map corrections if necessary.

Check the operation of sensor (1) using the DDS 2.

After selecting the proper items on the DDS 2 menu, read the external air temperature value among the different displayed parameters and compare it with the actual value. Change the sensor if reading is incorrect.

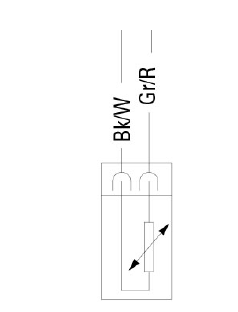

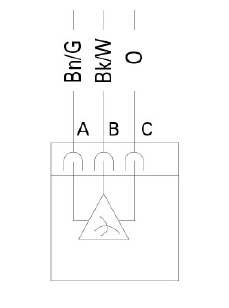

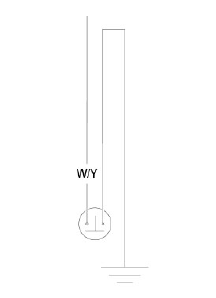

Electric diagram

Map Sensor

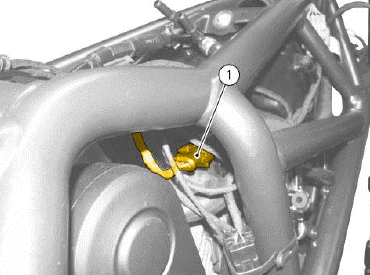

The Map sensor (Manifold Absolute Pressure) (1) measures the air pressure to calculate the exact quantity of fuel to be injected.

The control unit processes the intake air pressure value and the external temperature value to calculate the quantity of intake air in the cylinders and, based on the preset stoichiometric ratio, determines the correct quantity of fuel to be delivered to the injectors.

The air/fuel ratio is therefore always excellent.

Check the correct operation of MAP sensor (1) using the DDS 2.

Electric diagram

Oil pressure sensor

The oil pressure sensor (pressure switch) (1) is located on the oil cooler.

To test the operation of the engine oil pressure sensor (1), proceed as follows.

Use the diagnosis instrument DDS 2 to check that oil pressure in the engine lubrication circuit complies with the specified values.

If the engine oil pressure value is outside the specified range, check the lubrication circuit components and service as necessary.

Switch on the instrument panel (ignition key turned to ON) without starting the engine, disconnect the electrical terminal from the pressure sensor and connect it to ground:

- if the warning light does not illuminate, this means the sensor is defective and must be replaced;

- if the warning light illuminates, start the engine;

- if the warning light does not turn off, check the system with the DDS 2.

Electric diagram

Lambda sensor

The lambda sensor detects the presence of unburned fuel in the exhaust gases, processes the information sent to the control unit and allows keeping the mixture ratio (air kg/fuel kg) within the best efficiency range for the catalytic converter.

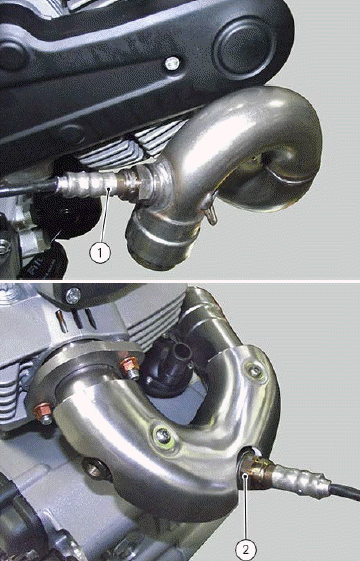

The vehicle is provided with two lambda sensors, one per cylinder:

- lambda sensor (1) for horizontal cylinder exhaust;

- lambda sensor (2) for vertical cylinder exhaust.

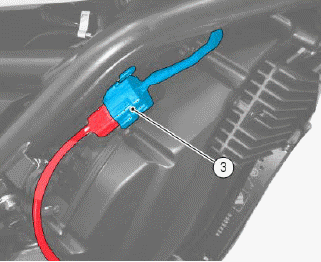

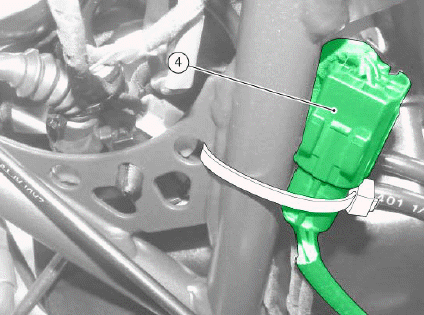

If it is necessary to reach the lambda sensor connectors, consider that:

- connector (3) of the horizontal cylinder lambda sensor is located on the vehicle front and lower side;

- connector (4) of vertical cylinder lambda sensor.

Check lambda sensors correct operation with the DDS 2 diagnosis instrument connected to control unit diagnostic socket.

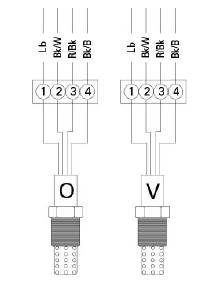

Electric diagram

See also:

Ducati Scrambler 800 - Service manual > Main relay and injection

Ducati Scrambler 800 - Service manual > Main relay and injection

To remove and refit the main relay, refer to chapter "Starting system". Timing/rpm sensor The engine rpm sensor (1) is an inductive sensor that detects the teeth of a phonic wheel by means of an alternate signal proportional to the teeth passage speed.

Ducati Scrambler 800 - Service manual > Stepper motor

Ducati Scrambler 800 - Service manual > Stepper motor

The stepper motor is useful when the engine does not reach a correct temperature. The stepper motor works on the throttle valve opening/closing.

Ducati Scrambler

Ducati Scrambler Fantic Caballero 500

Fantic Caballero 500 Indian FTR 1200

Indian FTR 1200 Moto Guzzi V85 TT

Moto Guzzi V85 TT Royal Enfield Bullet Trials Works Replica

Royal Enfield Bullet Trials Works Replica Triumph Scrambler 1200 XE

Triumph Scrambler 1200 XE Triumph Street Scrambler

Triumph Street Scrambler Yamaha XSR700

Yamaha XSR700 Ducati Scrambler 800

Ducati Scrambler 800 Moto Guzzi V85 TT

Moto Guzzi V85 TT Triumph Scrambler 1200 XC

Triumph Scrambler 1200 XC