Triumph Scrambler 1200 XE - Owner's Manual > Drive Chain

Triumph Scrambler 1200 XE - Owner's Manual > Drive Chain

Warning

Warning

A loose or worn chain, or a chain that breaks or jumps off the sprockets could catch on the engine sprocket or lock the rear wheel.

A chain that snags on the engine sprocket will injure the rider and lead to loss of motorcycle control and an accident.

Similarly, locking the rear wheel will lead to loss of motorcycle control and an accident.

For safety and to prevent excessive wear the drive chain must be checked, adjusted and lubricated in accordance with the scheduled maintenance requirements. Checking, adjustment and lubrication must be carried out more frequently for extreme conditions such as high speed riding, salty or heavily gritted roads.

If the chain is badly worn or incorrectly adjusted (either too loose or too tight) the chain could jump off the sprockets or break. Therefore, always replace worn or damaged chains using genuine Triumph parts supplied by an authorised Triumph dealer.

Drive Chain Lubrication

Lubrication is necessary every 200 miles (300 km) and also after riding in wet weather, on wet roads, or any time that the chain appears dry.

To lubricate the drive chain:

- Use the special drive chain lubricant as recommended in the Specifications section.

- Apply lubricant to the sides of the rollers then allow the motorcycle to stand unused for at least eight hours (overnight is ideal). This will allow the oil to penetrate to the drive chain O-rings etc.

- Before riding, wipe off any excess oil.

- If the drive chain is especially dirty, clean first and then apply oil as mentioned above.

Caution

Do not use a pressure washer to clean the drive chain as this may cause damage to the drive chain components.

Drive Chain Free Movement Inspection

Warning

Before starting work, make sure the motorcycle is stabilised and adequately supported.

This will help prevent injury to the operator or damage to the motorcycle.

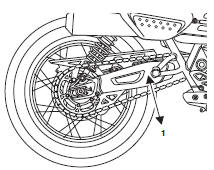

- Maximum movement position

To inspect the drive chain free movement:

- Place the motorcycle on a level surface and hold it in an upright position with no weight on it.

- Rotate the rear wheel by pushing the motorcycle to find the position where the drive chain is tightest, and measure the vertical movement of the drive chain midway between the sprockets.

Drive Chain Free Movement Adjustment

The vertical movement of the drive chain must be in the range 20 - 30 mm.

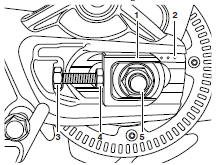

- Spindle adjuster

- Adjuster markings

- Adjuster bolt lock nut

- Adjuster bolt

- Rear wheel spindle nut

If the drive chain free movement measurement is incorrect, adjustments must be made as follows:

- Loosen the wheel spindle nut.

- Loosen the lock nuts on both the left hand and right hand drive chain adjuster bolts.

- Move both adjusters by an equal amount using the adjuster markings as a guideline.

- Turn the adjuster bolts clockwise to increase drive chain free movement and anticlockwise to reduce drive chain free movement.

- When the correct amount of drive chain free movement has been set, push the wheel into firm contact with the adjusters.

- Make sure the same adjuster marking is aligned with the spindle adjuster on both sides of the swinging arm.

- Tighten both adjuster lock nuts to 20 Nm and the rear wheel spindle nut to 110 Nm.

- Repeat the drive chain adjustment check. Readjust if necessary.

Warning

Operation of the motorcycle with insecure adjuster lock nuts or a loose wheel spindle may result in impaired stability and handling of the motorcycle.

This impaired stability and handling may lead to loss of control or an accident.

- Check the rear brake effectiveness.

Rectify if necessary.

Warning

It is dangerous to operate the motorcycle with defective brakes; you must have your authorised Triumph dealer take remedial action before you attempt to ride the motorcycle again.

Failure to take remedial action may reduce braking efficiency leading to loss of motorcycle control or an accident.

Drive Chain and Sprocket Wear Inspection

Warning

Never neglect drive chain maintenance and always have drive chains installed by an authorised Triumph dealer.

Use a genuine Triumph supplied drive chain as specified in the Triumph Parts Catalogue.

The use of non-approved drive chains may result in a broken drive chain or may cause the drive chain to jump off the sprockets leading to loss of motorcycle control or an accident.

Caution

If the sprockets are found to be worn, always replace the sprockets and drive chain together.

Replacing worn sprockets without also replacing the drive chain will lead to premature wear of the new sprockets.

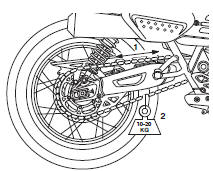

- Measure across 20 links

- Weight

To inspect the drive chain and sprocket wear:

- Remove the drive chain guard.

- Stretch the drive chain taut by hanging a 10 - 20 kg (20 - 40 lb) weight on the drive chain.

- Measure the length of 20 links on the straight part of the drive chain from pin centre of the 1st pin to the pin centre of the 21st pin. Since the drive chain may wear unevenly, take measurements in several places.

- If the length exceeds the maximum service limit of 320 mm, the drive chain must be replaced.

- Rotate the rear wheel and inspect the drive chain for damaged rollers, and loose pins and links.

- Also inspect the sprockets for unevenly or excessively worn or damaged teeth.

Note

Illustration shows wear on sprockets mounted on the left hand side of the motorcycle.

For sprockets mounted on the right hand side of the motorcycle, the wear is on the opposite side of the tooth.

- If there is any irregularity, have the drive chain and/or the sprockets replaced by an authorised Triumph dealer.

- Refit the chain guard and tighten the front fixing to 4 Nm and the rear fixing to 9 Nm.

See also:

Triumph Scrambler 1200 XE - Owner's Manual > Throttle Control

Triumph Scrambler 1200 XE - Owner's Manual > Throttle Control

Warning Always be alert for changes in the 'feel' of the throttle control and have the throttle system checked by an authorised Triumph dealer if any changes are detected. Changes can be due to wear in the mechanism, which could lead to a sticking throttle control.

Triumph Scrambler 1200 XE - Owner's Manual > Brakes

Triumph Scrambler 1200 XE - Owner's Manual > Brakes

Brake pads Minimum thickness line Brake pads must be inspected in accordance with scheduled maintenance requirements and replaced if worn to, or beyond the minimum service thickness.

Ducati Scrambler

Ducati Scrambler Fantic Caballero 500

Fantic Caballero 500 Indian FTR 1200

Indian FTR 1200 Moto Guzzi V85 TT

Moto Guzzi V85 TT Royal Enfield Bullet Trials Works Replica

Royal Enfield Bullet Trials Works Replica Triumph Scrambler 1200 XE

Triumph Scrambler 1200 XE Triumph Street Scrambler

Triumph Street Scrambler Yamaha XSR700

Yamaha XSR700 Ducati Scrambler 800

Ducati Scrambler 800 Moto Guzzi V85 TT

Moto Guzzi V85 TT Triumph Scrambler 1200 XC

Triumph Scrambler 1200 XC