Ducati Scrambler 800 - Service manual > Diagnostic socket

Ducati Scrambler 800 - Service manual > Diagnostic socket

The diagnostic socket is located in the vehicle rear side. In order to reach it, remove the seat (Removing the seat).

Left-hand switch

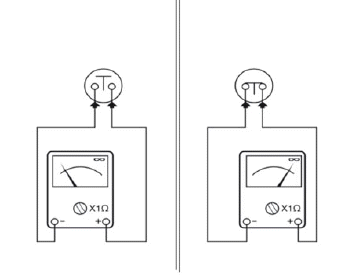

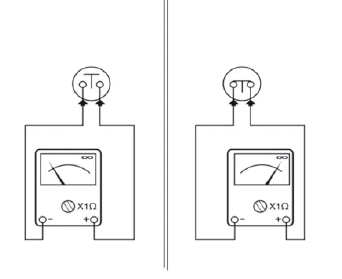

In the event of a fault, the internal connections of the device must be checked in all operating conditions. It is therefore necessary to disconnect the main wiring switch connector and perform the check using an analogue or digital multimeter.

Note The same test may be done using the "DDS 2" diagnosis instrument.

LEFT-HAND SWITCH CONTROL

Remove the LH handgrip as described in chapter "Removing the handlebar".

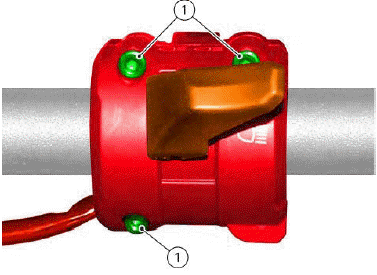

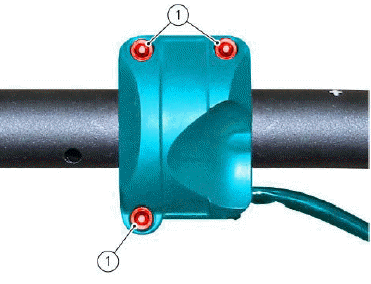

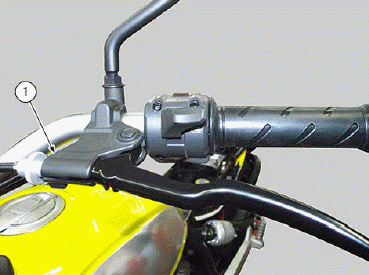

Loosen the screws (1) and remove the left-hand switch.

The colours mentioned in the following descriptions refer to the colour of the wires from the switch and not to the colour of the main electric system wires.

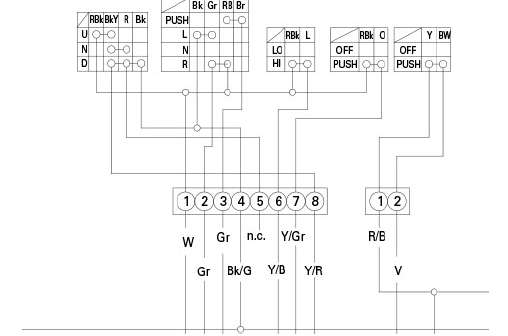

Electric diagram

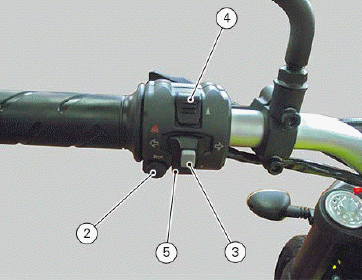

CONTROLS ON LEFT-HAND SWITCH

HORN button (2)

Connect the terminals of a multimeter to the Yellow and White/Blue cables to check for electric continuity, which must be available when HORN is pressed.

- When the HORN button is pressed, the resistance value read by the multimeter should be close to zero and, if available, a continuity beep should be heard.

- When the HORN button is not pressed, the resistance value should be

infinity (there is no continuity as the electrical contacts inside the push-button

are open) and no continuity beep should be heard, if provided.

If these conditions are not met, the device must be replaced.

Turn indicator switch (TURN) (3)

The turn indicators cancel button may also be used in the instrument panel for the CONFIRM MENU function, for selecting the riding mode.

Push this button for 3 seconds to the left side to activate the "Hazard" function (all 4 turn indicators).

Connect the multimeter to the Red/Blue and Grey wires arriving from the turn indicator switch and check for electrical continuity when operating the right turn signal.

Repeat the above procedure for the left turn indicator, but connect the multimeter to the Black and Grey wires.

Control switch (SET UP) (SET DOWN) (4) (5)

Buttons used to display and set instrument panel parameters.

Connect the multimeter to the Red and Black wires arriving from the instrument panel function selector switch and check for electrical continuity when pressing button (5).

Repeat the same procedure, press button (4) and connect the multimeter to the Red/Black and Blue/Yellow wires.

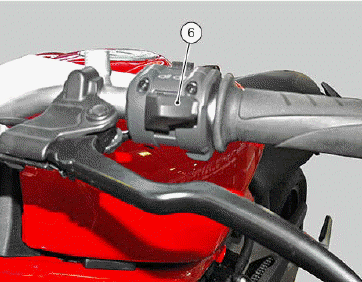

Low beam and high beam (Hi Beam) (6)

Test using the same procedure, applying the probes of the meter to the Red and Blue wires and moving switch down.

Flash switch (PASSING) (6)

The high-beam flash button may also be used for LAP functions.

Check for continuity between the Red and Orange wires.

Unlike the Hi Beam, switch (6) should be pressed.

For the refitting procedure refer to chapter "Refitting the handlebar".

Right-hand switch

In the event of a fault, the internal connections of the device must be checked in all operating conditions. It is therefore necessary to disconnect the main wiring switch connector and perform the check using an analogue or digital multimeter.

Note The same test may be done using the "DDS 2" diagnosis instrument.

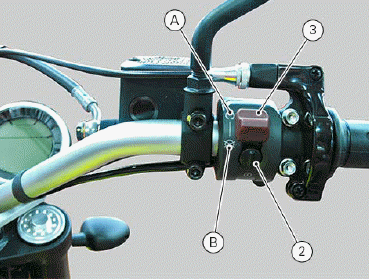

RIGHT-HAND SWITCH CONTROL

Remove the RH handgrip as described in chapter "Removing the handlebar".

Loosen screws (1) and remove the right-hand switch by disconnecting it from the main connection. The colours mentioned in the following descriptions refer to the colour of the wires from the switch and not to the colour of the main electric system wires.

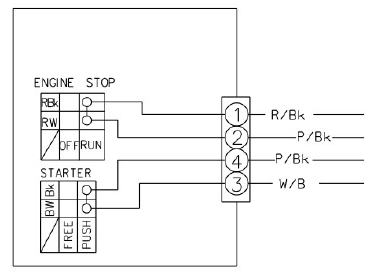

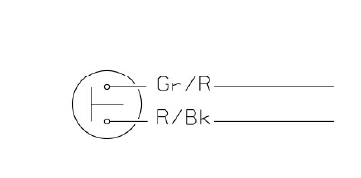

Electric diagram

CONTROLS ON RIGHT-HAND SWITCH

Engine stop button

Using a multimeter, check for continuity between the Red/White and Red/Black wires:

- when button (3) is in RUN position (A), there should be electrical continuity between the two wires;

- when the button is in the OFF position (B), there should be no

electrical continuity between the two wires.

If these conditions are not met, the engine stop switch is not working correctly and must be replaced.

Starter button

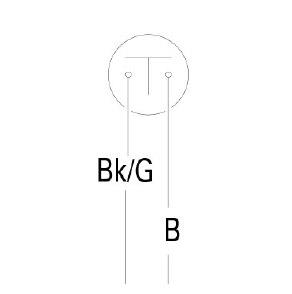

Proceed as described for the engine stop button and check for continuity between the Blue/White and Black wires when the starter button (2) is pressed.

If there is no continuity, the starter button is faulty and must be replaced.

Colours mentioned in the descriptions refer to the colour of wires from the switch and not to the colour of the main electric system wires.

For the refitting procedure refer to chapter "Refitting the handlebar".

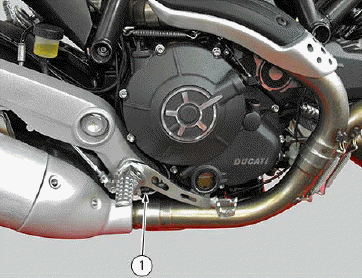

Rear stop switch

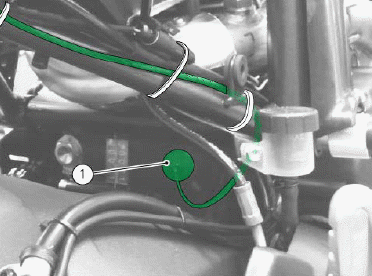

The rear STOP switch (1) is located inside the RH footpeg holder plate.

REAR STOP SWITCH CONTROL

To check operation of the rear (1) STOP switch, use a multimeter: when the rear brake lever is operated, there must be electric continuity between the terminals of the corresponding switch.

No electric continuity should be available when brakes are not operated.

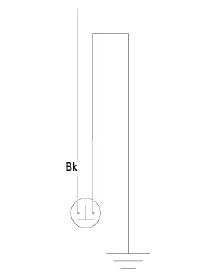

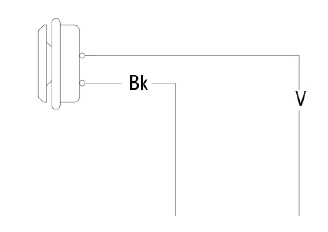

Electric diagram

If these tests fail to produce positive results, the part in question must be replaced.

Gear/neutral sensor

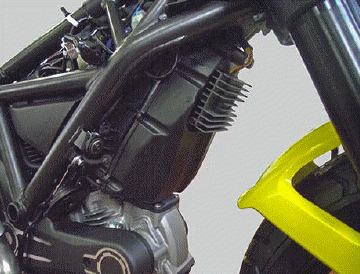

The gear sensor (1) is positioned on the vehicle rear RH side, near the solenoid starter.

To check the operation of gear sensor (1), connect the DDS 2.

Electric diagram

Horn

Supply 12 V (battery) to the two fastons.

With a multimeter connected between the two poles (threaded pins) of the solenoid starter, check for electric continuity.

If there is no electric continuity, ensure that the terminals are not oxidised and apply water repellent spray.

Change the horn if the malfunction persists.

Electric diagram

Clutch switch

The clutch switch (1) is located on the clutch lever lower side.

CLUTCH SWITCH CONTROL

To check operation of the front (1) STOP switch, use a multimeter: when the front brake lever is operated, there must be electric continuity between the terminals of the corresponding switch.

No electric continuity should be available when brakes are not operated.

If these tests fail to produce positive results, the part in question must be replaced.

Electric diagram

See also:

Ducati Scrambler 800 - Service manual > Main relay and injection

Ducati Scrambler 800 - Service manual > Main relay and injection

To remove and refit the main relay, refer to chapter "Starting system". Timing/rpm sensor The engine rpm sensor (1) is an inductive sensor that detects the teeth of a phonic wheel by means of an alternate signal proportional to the teeth passage speed.

Ducati Scrambler

Ducati Scrambler Fantic Caballero 500

Fantic Caballero 500 Indian FTR 1200

Indian FTR 1200 Moto Guzzi V85 TT

Moto Guzzi V85 TT Royal Enfield Bullet Trials Works Replica

Royal Enfield Bullet Trials Works Replica Triumph Scrambler 1200 XE

Triumph Scrambler 1200 XE Triumph Street Scrambler

Triumph Street Scrambler Yamaha XSR700

Yamaha XSR700 Ducati Scrambler 800

Ducati Scrambler 800 Moto Guzzi V85 TT

Moto Guzzi V85 TT Triumph Scrambler 1200 XC

Triumph Scrambler 1200 XC