Ducati Scrambler 800 - Service manual > Checking the engine timing

Ducati Scrambler 800 - Service manual > Checking the engine timing

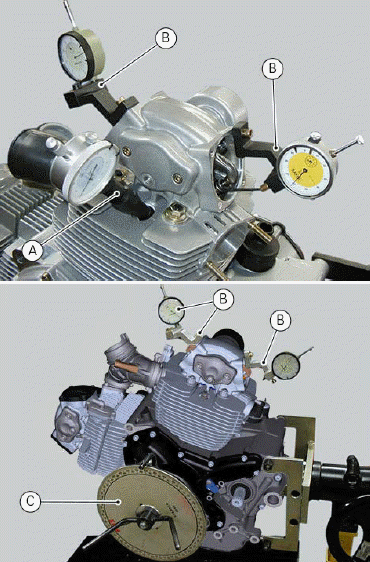

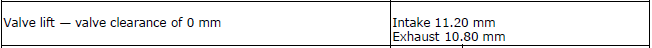

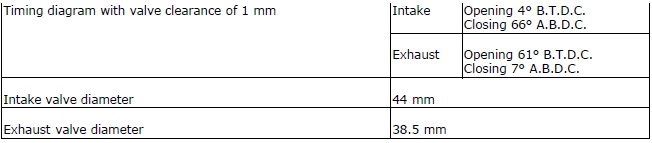

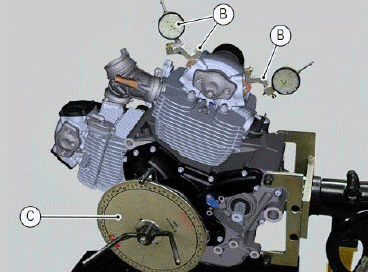

Remove the spark plugs and install tool (A) no. 88765.1297 in the spark plug bore to determine the piston TDC, fit gauges (B) no. 88765.1581 and the timing check tool with degree wheel (C) no. 88713.0123.

Set the opening valve clearance to zero when the camshafts are in rest position by fitting a feeler gauge, of suitable thickness, between the opening rocker arm and the opening shim.

Check that in this condition the camshaft can rotate. If it moves stiffly, use a thinner feeler gauge.

In this condition, with the piston of the horizontal cylinder at TDC with the valves fully closed as confirmed by the reading with gauge (A), set the gauges (B) to zero.

Tension the belts according to the value specified in paragraph "Changing the timing belts".

Turn the degree wheel (C) counter clockwise until the gauge dial (B), on the exhaust side, shows a lift of 1 mm.

Check that the value of the angular displacement read on the degree wheel (C) is the specified one.

Continue to rotate in the same direction until you obtain a lift of 1 mm on the intake side.

Check the angular value on the degree wheel.

Continue to rotate until you obtain an intake valve lift of 1 mm on the gauge (B), during closure of the valve for the compression stroke.

Check the angular displacement value with the specified one.

Continue to rotate the degree wheel counter clockwise until you obtain a lift of 1 mm of the exhaust valve, when opening or closing the valve.

Check the angular displacement value against the specified value.

Repeat the procedure for the vertical cylinder.

A tolerance of +-3Вє is allowed in the values detected with the described procedure compared to the specified ones.

Checking valve lift

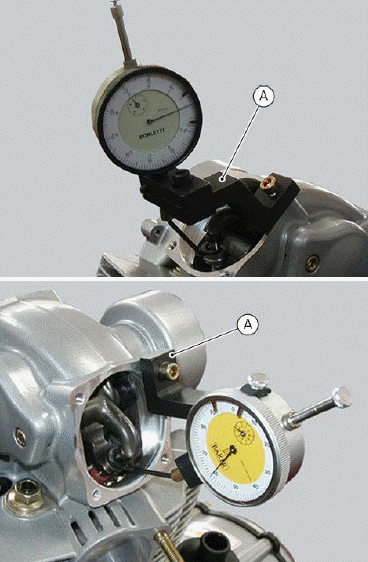

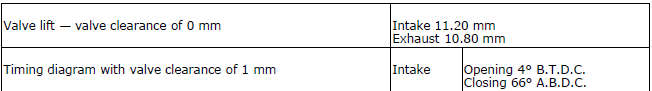

Fit gauge (A) part no. 88765.1581 in the hole of the removed head cover as shown in the figure.

Set the opening valve clearance to zero when the camshafts are in rest position by fitting a feeler gauge, of suitable thickness, between the upper rocker arm and the opening shim.

Check that the feeler gauge fork probe is centred on the valve axis and against the closing shim collar.

Set the dial gauge to zero when the valve is fully closed.

Rotate the intake camshaft so as to allow the intake valves to lift fully.

Check on the dial gauge that the measured value corresponds to the prescribed one.

Perform the same operation for the exhaust valve, by fixing the support on the cylinder head opposite side.

Refit the components by carrying out the same operations indicated in paragraph "Checking and adjusting the valves" described above.

See also:

Ducati Scrambler 800 - Service manual > Checking and adjusting the valve clearance

Ducati Scrambler 800 - Service manual > Checking and adjusting the valve clearance

Remove the seat (Removing the seat). Remove the fuel tank (Removing the fuel tank). Remove the blow-by (Removing the airbox). Remove the following parts from the electrical component box: Battery; Starter relay; Fuse box;

Ducati Scrambler

Ducati Scrambler Fantic Caballero 500

Fantic Caballero 500 Indian FTR 1200

Indian FTR 1200 Moto Guzzi V85 TT

Moto Guzzi V85 TT Royal Enfield Bullet Trials Works Replica

Royal Enfield Bullet Trials Works Replica Triumph Scrambler 1200 XE

Triumph Scrambler 1200 XE Triumph Street Scrambler

Triumph Street Scrambler Yamaha XSR700

Yamaha XSR700 Ducati Scrambler 800

Ducati Scrambler 800 Moto Guzzi V85 TT

Moto Guzzi V85 TT Triumph Scrambler 1200 XC

Triumph Scrambler 1200 XC